About the Author

Ewell White Barr (1893-1968) was born to Rev. William C. Barr (1867-1953) and Gillie Shelton Barr (1874-1950). His father was a preacher and a farmer in the Banister district of Pittsylvania County, Virginia. His paternal Barr ancestors were Pennsylvania Germans who traveled to Virginia by way of Ohio. Through his maternal side, his Shelton family settled in his local area prior to the American Revolution when his ancestor Daniel Shelton (1729-1809) journeyed from Middlesex County.

Ewell was raised on his father’s farm, where he worked for the first twenty-nine years of his life. His obituary states that in 1922 he moved to the city of Danville where he worked as a “tobacconist” for his entire life. He started out working for Holland’s Warehouse as a buyer and seller of tobacco. In 1924, Ewell married Mabel Rogers (1898-1985) and they lived in a house on Pine Street. There they raised one child, William Ewell Barr, who later became an attorney in Danville.

In the early 1930’s, Ewell typed up a thesis on “Leaf Tobacco Grading.” The paper is not dated, except for mention of several months throughout 1933 and 1934 as if they are near the present time. It is unknown to me who exactly this paper was submitted to or what it has been used for. It goes into great detail about the systematic labeling of different qualities of loose leaf tobacco. By the time of Ewell’s death, he was working for Producer’s Warehouse in Danville.

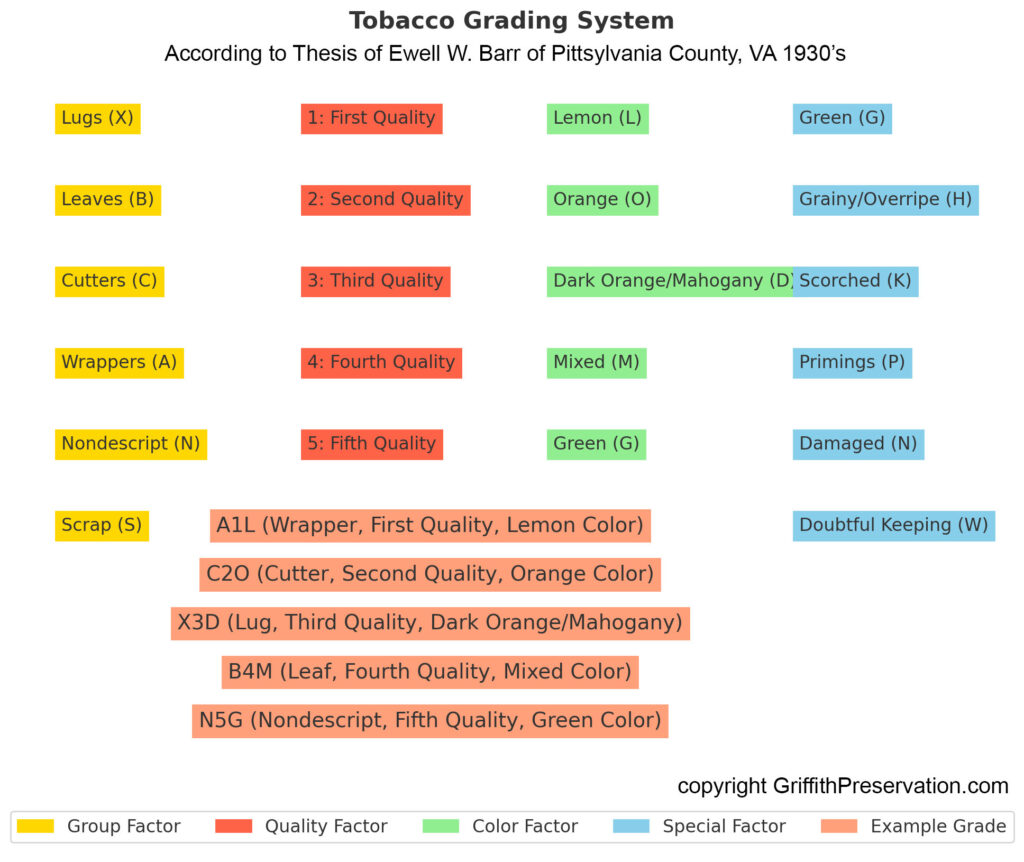

By using the information in his thesis, this graphic has been created to organize each quality for leaf grading.

**The following transcription includes the original spelling. This document was acquired from the collection of the late historian Danny Ricketts of Danville. Scans of the original paper are attached at the end of the article.

Leaf Tobacco Grading.It can, I think, be said with a large degree of accuracy, wherever tobacco has been grown, whether in the states or in foreign countries, the producer thereof has long since realized the all importance of grouping his leaf tobacco in order to secure therefor the best price possible. The producer’s experience has taught him that a single stalk of tobacco may contain as many as three or more different grades and groups of tobacco, and this can be expecially said with reference to American types of tobacco. This performance on the part of the producer is merely the sorting or assorting of his tobacco as distinguished from grading of same. In a crude sort of way he designates and calls these assortments lugs, fillers or wrappers, each assortment of which may consist of one or more kinds or grades of tobacco, depending in the main on uniformity of quality, color and length.

To a remarkable degree by an application of common sense, he has been able to so assort his tobacco as to conform with some one grade of tobacco which the commercial purchaser desires and to secure therefor such a price as the purchaser has fixed for that particular grade.

The very nature of tobacco, expecially of the types of which I am discussing, requires a somewhat technical system of grading since so many elements exist in its general makeup. As many perhaps as twenty-five elements may or may not enter into a certain type of tobacco, for example, the elements of quality of tobacco such as color, texture, smoothness, soundness, length, body, fibre, strength and many other elements not mentioned here are to be considered in any system of efficient grouping and grading of tobacco, many of which elements go back for their origin to the nature of the soil upon which the tobacco grew, climatic conditions as during its growth and maturity, the manner of cutting, curing and conditioning for market.

The experience of the writer has taught him that a standard system of grading of tobacco, properly and efficiently applied, is most important and can be made most profitable. For many reasons, few of which are here expressed,

- Because the purchaser demands that it be graded.

- The price is fixed according to grades.

- A lot or pile of tobacco containing one or more grades commands only that price fixed for the lowest grade.

- It is utilized and consumed in different ways and for different purposes.

- Each manufacturer requires certain grades for his particular blend of smoker’s, chewers, etc.

- A standard grading system tends to standardization of price.

- It affords the purchaser some idea of the value of his product.

- Economically sound.

For the purposes herein sought to be accomplished this discussion is confined to those types of tobacco produced in the United States, in the states of Virginia, North Carolina, South Carolina and Georgia, of which the writer is fairly familiar and generally grown in what is known as the Old Flue Cured Belt, the Eastern Flue Cured Belt, Southeastern Flue Cured Belt and the Southern Flue Cured Belt known and designated by the Bureau of Agricultural Economics of the United States, Department of Agriculture, as types 11, 12, 13 and 14 respectively. From the types we derive groups of tobacco such as lugs, leaves, cutters, wrappers, nondescript and scrap. Designated by the standard above mentioned by the symbols A, B, C, X, N. S. Thus we attain what is known and called the group factor. We come next to other factors necessary to a well devised and efficient system of grading, such as quality factor, color factor and special factor.

The quality factor is designated by figures adopting number one as a representation of the first quality, 2- second quality, 3- third quality, 4- fourth quality, 5- fifth quality, etc. This factor is highly technical due to the nature of the subject matter here dealt with and many elements are involved in the quality factor, such as body, color, curing, elasticity, fibre, size and color, finish, grain, injury, length, maturity, oil, shape, smoothness, solidity, soundness, strength, texture, tissue, uniformity, venation, wax, width, each element of which have many characteristics which are to be applied in arriving at the degree of quality for the purpose of correct and efficient grading.

We come next to the color factor, the same being designated by alphabet symbols as L for lemon, F for orange, D for dark orange or mahogany, M for mixed, G for green. Thus we may have a lemon wrapper, a lemon cutter and a lemon lug and likewise as to the orange color and the dark mahogany. Thus we have the group, the quality and the color in arriving at a key to the grading system.

There is another factor important with reference to the grading of tobacco and that is what is designated in the standard grade as the special factor. This factor is utilized and adopted for the purpose of denoting some existing characteristic not governed by the regular or ordinary grade factors. The special factor abbreviations may be expressed in alphabet symbols such as G meaning green, H meaning grainy or overripe, K meaning scorched, P, primings, N, damaged, W, doubtful keeping condition, etc.

Thus if A represents wrapper and the figure 1 represents first quality, and L represents the lemon color and 0 the orange color, we get the key for the first If cutters C1L in lemon and C10 grade. For wrappers A1L, for the orange color A10. in orange color. If lugs X1L in lemon or X10 in orange. With any additional symbols so designated and required in denoting special factors. Thus systematically carried through we have the key for the leaf, for the cutters, for the lugs, for the nondescript or the scrap.To the writer the most interesting feature in connection with tobacco grading is the matter of determining the quality of tobacco which complies with the grade of the first quality, the grade of the second quality, third quality, fourth quality and so on. While the group factor, color factor and special factor, are most important, the real test in the opinion of the writer comes in determining the quality factor. There are two ways to determine this factor, namely by sight and by touch. These two methods are dependent upon each other to a large extent in order to arrive at the quality of leaf tobacco for the purpose of a correct and efficient grading system. While some grades might be determined mainly by sight alone, the trained sense of touch auguments the ability to a large extent to properly grade when one comes to differenate between Al and A2 and A3 of the lemon grades or Al, A2 and A3 of the orange grades, and the same applies to dark orange or mahagony.

By sight one can readily determine cleanliness in tobacco, ripeness, color, nature of fibre, uniformity and tolerance, but soundness, silkiness, elasticity, amount of oil, strength, extent of spread and the degree of wax can best be determined by the combined senses of sight and touch.

Justification for Grading

From the experience which the writer has had in the handling of tobacco, he is convinced that the producer thereof has suffered an inestimable loss for the want of a general application of a standard grading system of tobacco for all American types. Such a system would apply alike to the tobacco of every producer of the same type, group and grade. It would apply alike to all commercial purchasers of tobacco. It would afford an opportunity to the producer to determine whether or not he had secured a fair price for his product, it would tend to standardize the price of tobacco and in the opinion of the writer this latter advantage alone would justify a standard system of grading. The result might be the elimination of the present auction system, which in many respects without doubt, is bad. It is very likely that the tremendous costs attached to the present system of selling and buying of leaf tobacco could be used to increase the present price paid by purchasers and thereby more adequately and justly compensate the producers for this product.Of all the millionaires or semi-millionaires whom the tobacco industry has made, scarcely one is a producer, and whether the item last above expressed be economically just or unjust, sound or unsound, the fact is that such imperfect grading system now generally applied, has largely contributed to the exhausted financial plight in which the average tobacco producer finds himself, year in and year out. Any industry that yields for any government the revenue that is derived from tobacco culture and which has so handsomely enriched manufacurers, dealers and purchasers thereof, deserves the most economic and scientific methods in the disposition thereof that is possible to devise.

To illustrate: There are eight auction warehouses operated in the City of Danville for the season of 1933 and 1934, a period covering five months beginning October, 1933, and ending March, 1934. The sum of $120,000.00 roughly estimated will be contributed by the producers to these warehouses for the privilege and services in the sale of tobacco for the season specified, the poundage of which will approximate 40,000,000. If seven tobacco companies, and I think this number is fairly correct, are regular buyers on the Danville market, and each company maintains four buyers on the daily sales at an average salary of $300.00 per month, and if the seven companies will pay approximately $100,000.00 per year in salary ” five such markets are operating in the Old Belt, over $1,000,000.00 will be expended under the present system, whereas with a uniform or standard system of grading universally applied to the tobacco industries, for the City of Danville, Virginia, one warehouse would be ample for said city and one buyer for each company could buy as much tobacco in one day as all four buyers could purchase in a week or a month for that matter, thereby diverting this tremendous expenditure, necessary no doubt under the present system, but not necessary under a well executed standard grading system, to that phase of the tobacco industry well deserved but scarcely realized.

Respectfully submitted,Ewell White Barr

Margaret Gupton

Connie Davis